The lift trucks are used to unload, lift, lower and stack pallet loads, or other bulk loads into storage and transportation racks and facilities. Items such as computers, drums, corrugated boxes, plastic bottles, furniture and beverages are examples of products which are stacked onto pallets and moved by reach trucks. Read More…

MHS Lift offers material handling equipment solutions, offering lift trucks, aerial equipment, personal carriers, floor cleaning equipment, parts, and integrated solutions. With a commitment to quality and customer satisfaction, MHS Lift delivers reliable, efficient, and innovative equipment designed to enhance productivity and safety in various industrial and commercial applications. MHS Lift...

Our goal at Crown Equipment Corporation is to provide you with the very best forklift trucks. These items are extremely reliable and can handle the toughest loads. We are eager to work with your business. We offer competitive pricing for premium quality forklifts.

Our solutions are guaranteed to help you save in operation costs. Our systems can easily be integrated with your facility and we strive to match your exact needs. Our engineers manufacture very powerful narrow aisle forklifts. It is our hope to create a long lasting business relationship with you. We engineer and fabricate a wide selection of heavy duty forklift trucks which are available new,...

There are a number of innovations emerging in the lift truck industry and we are a front runner of these newer technologies. The operations and advantages of our forklifts are unsurpassed. You can visit our website to receive full readouts regarding the attributes and capabilities of our lift trucks. We are happy to say that we are industry leaders for sales of quality lift trucks! Feel free to...

We have been providing material handling lifts and forklift truck equipment since 1984. Our forklifts and used forklift trucks range from 3,000 - 100,000 pounds. At Alta Lift Truck Services we are Michigan's premier choice with 8 locations, ISO 9001:2000 certified, and 24/7 service.

More Reach Truck Manufacturers

Efficient storage is an operational focus for many warehouse and industrial space owners and forklift trucks allow a company to make the most of their vertical storage capacity. Industrial trucks can lift and lower thousands of pounds of goods on the lifting mechanism attached to them. Reach trucks are often designed to work within narrow aisles and confined storage spaces, and are able to be tightly maneuvered around corners and shelves.

They consist of outriggers, or stabilizing arms, which are in the front of the truck. The telescoping forks are equipped with hydraulic lifting systems which raise the forks or lifting platform to reach pallets and items on the high shelves or racks. For intensive applications, a high strength, heavy duty mast can be used to provide support to the extra weight.

Constructed with either internal combustion engines or electric motors, reach trucks come in three main types: straddle reach trucks, standup reach trucks or double deep reach trucks. Straddle trucks have wider bases in order to provide stability for raising very heavy loads to maximum height. Standup trucks lift and slide pallets in a simple movement and double deep trucks have extra long forks which are able to be used in two pallet deep shelving systems.

Often one or more of these three types of reach trucks are used in warehouses. Many advantages exist for using reach trucks. They improve productivity, storage density, space utilization as well as offering easy pallet load retrieval. They cut back on labor costs however; length operator training is required to prevent accidents and product loss.

The complexity of the operator controls, the caution with which trucks much be operated and the care required in moving heavy and sometimes precarious loads are all elements of risk with fork lift truck use. In addition, while reach trucks can be used at heights up to 40ft, this position places physical strain upon the operator's neck and eyes and so it not a recommended height for frequent use.

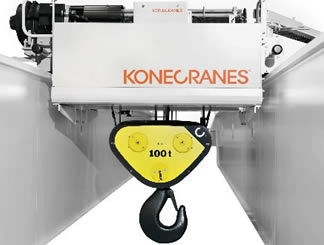

Cranes

Cranes Electric Hoists

Electric Hoists Forklifts

Forklifts Hydraulic Lifts

Hydraulic Lifts Rope

Rope Wire Rope

Wire Rope AGV

AGV Air Pollution Control

Air Pollution Control Assembly Machinery

Assembly Machinery Blowers

Blowers Conveyors

Conveyors Cranes

Cranes Deburring Machinery

Deburring Machinery Dust Collectors

Dust Collectors Heaters

Heaters Hose Reels

Hose Reels Lubricators

Lubricators Mezzanines

Mezzanines Modular Buildings

Modular Buildings Storage Racks

Storage Racks Ultrasonic Cleaners

Ultrasonic Cleaners Work Benches

Work Benches