Forklifts, or forklift trucks, are industrial trucks designed to lift and move loads. Forklifts can increase efficiency, reduce the risk of injury, and enhance storage space. Forklift trucks have an extensive range of lifting capabilities. They can lift and move anything from bulk materials to heavy duty equipment. Read More…

MHS Lift offers material handling equipment solutions, offering lift trucks, aerial equipment, personal carriers, floor cleaning equipment, parts, and integrated solutions. With a commitment to quality and customer satisfaction, MHS Lift delivers reliable, efficient, and innovative equipment designed to enhance productivity and safety in various industrial and commercial applications. MHS Lift...

Our goal at Crown Equipment Corporation is to provide you with the very best forklift trucks. These items are extremely reliable and can handle the toughest loads. We are eager to work with your business. We offer competitive pricing for premium quality forklifts.

Our solutions are guaranteed to help you save in operation costs. Our systems can easily be integrated with your facility and we strive to match your exact needs. Our engineers manufacture very powerful narrow aisle forklifts. It is our hope to create a long lasting business relationship with you. We engineer and fabricate a wide selection of heavy duty forklift trucks which are available new,...

There are a number of innovations emerging in the lift truck industry and we are a front runner of these newer technologies. The operations and advantages of our forklifts are unsurpassed. You can visit our website to receive full readouts regarding the attributes and capabilities of our lift trucks. We are happy to say that we are industry leaders for sales of quality lift trucks! Feel free to...

We have been providing material handling lifts and forklift truck equipment since 1984. Our forklifts and used forklift trucks range from 3,000 - 100,000 pounds. At Alta Lift Truck Services we are Michigan's premier choice with 8 locations, ISO 9001:2000 certified, and 24/7 service.

More Forklift Manufacturers

Customers purchase them for use in a wide variety of industries, such as materials handling, shipping and handling, manufacturing, aerospace, automotive, marine, product handling, and more.

In industrial or commercial warehouses, forklift trucks are used to lift, move, and load heavy pallets that are used to store products. Forklift trucks are also useful on construction sites, loading docks, or in storerooms. To maximize storage space, operators also forklifts to stack loaded pallets on top of each other. They can make the stacks as high as the forklift can reach.

History

Long before manufacturers began employing forklifts, Blaise Pascal discovered hydraulic power. Hydraulics are the branch of science on which the function of forklifts was originally based. What Pascal discovered at that time (between 1647 and 1648) was that if you put pressure on one area of contained, impressible liquid, that pressure will spread to the rest of the liquid. Along with that, if you create an outlet channel, the liquid will leave through it carrying that same pressure.

Based on what we now call Pascal’s Law, all hydraulic systems work. The first forklifts, which were developed during World War I, used hydraulic power. American companies developed them to assist them in various lifting-related manufacturing tasks. They were necessary at that time because so many of their workers were overseas fighting in the War.

The first company to begin selling forklifts, Clark, originally called them “Trucktractors,” since they were essentially tractors combined with trucks. The first company to modify them to feature the ability to lift loads above truck height was Yale & Towne. They did so in 1923.

After World War I, forklifts gained popularity for their ability to lift and move the newly standardized pallet. Then, when World War II broke out, forklift manufacturers produced forklifts on a large scale, so that armies and military manufacturers could ship large amounts of materials and weapons quickly.

During the years immediately following World War II, engineers made a great many improvements to forklift design. Such improvements included the addition of safety cages for operators, the addition of battery power capabilities, increased lifting abilities (higher heights, heavier loads), and better maneuverability in awkward and narrow spaces.

Between the 1960s and 1980s, engineers added features like counterbalances and electronic controls. Since then, as CNC technology and automation has improved by leaps and bounds, so have the associated capabilities of forklift trucks.

Forklift sales are steady and the forklift market is ripe with competition. Electric forklifts are gaining popularity in many facilities due to increasingly strict emissions standards.

How It Works

In most forklifts, a hydraulic system is what gives the lifting mechanism its power and makes it possible to carry so much weight at one time. Some forklifts have electric actuator-controlled lifts, but these are rarer.

Hydraulic and electric forklifts work using one of three control styles: manual, motorized, or automated.

Manual forklifts are operated by a person working behind them. They move loads manually.

Motorized forklifts are operated by a driver who either sits or stands in them. They are best for long distance load transportation.

Automated forklifts work using computer designed guidance systems. They do not require humans to operate them. They are most common in industries like automotive manufacturing and aerospace.

Types

If you are looking for one or more forklifts, you have many options available to you. Some of the many standard forklift types that forklift suppliers sell include walkie forklifts, sideloaders, platform trucks, straddle trucks, stand up forklifts, narrow aisle forklifts, order picker trucks, and turret forklifts.

Walkie forklifts are electric forklifts that allow forklift operators to safely drive them on smooth concrete in indoor settings. The reason they allow this is their wheels, which are designed for motion on smooth concrete.

Sideloaders have a lifting platform that extends from the side of the forklift, while all other types have a lifting platform on the front of the vehicle. Heavy duty lift applications require the use of sideloaders.

Platform trucks are not technically a type of industrial forklift, but they are a type of industrial truck that can be used in some similar applications. Most often, this is when a pallet needs to be moved across a floor or loaded into a tractor trailer. A platform truck is composed of a simple flatbed on wheels that can fit under a pallet. Operators use a handle to control manual transportation, and a lever allows them to raise or lower a load just a few inches off of the ground. If a lift is expected to carry extremely heavy loads, manufacturers can add stabilizing bars to reinforce the platform as it raises and lowers loads.

Straddle trucks are a type of forklift that feature a wider base than a typical forklift. Manufacturers design them with this base so that they can operate in heavy duty settings and lift large loads higher than normal forklifts.

Stand up forklifts are small forklifts designed for expedience. They do not offer a place for the operator sit, which is why they’re called stand up forklifts. Using stand up forklifts, operators can perform quick and frequent indoor loading and unloading tasks. Because they are small, stand up forklifts are especially useful in tight spaces.

Narrow aisle forklifts are specifically designed to move in small spaces.

Order picker trucks, also known as reach trucks or warehouse forklifts, allow warehouse workers to reach products or equipment (equipment forklifts) stored on high shelves. They often do so in the service of filling orders, thus the name.

Turret forklifts can raise a load high off of the ground and rotate it at a 90-degree angle.

All of these forklifts fall into one of seven forklift classes. These classes divide the forklifts based on factors like the type of tires used and the engine type. To a lesser degree, these classes also consider forklift counterbalancing methods. (Counterbalancing is the use of weighted items to keep the forklift from falling over from too much weight.)

Class 1 forklifts are electric motor rider trucks. They may be either seated or stand-up models with three-wheel designs. Usually, they feature counterbalancing in the form of pneumatic wheels or cushioning.

Class 2 forklifts are narrow aisle electric motor forklifts. Narrow aisle forklift trucks allow operators to maneuver in small spaces, like narrow aisles. To assist with user applications, class 2 forklift equipment may have swing mast or extra reach features.

Class 3, or electric hand riders, are forklifts that operators operate either while walking behind or standing on them. Examples of class 3 forklifts include high lift forklifts and pallet lift trucks (pallet trucks).

Class 4 forklifts are those forklifts that feature internal combustion engines and cushion tires (cushion tire forklifts). Typically, they also have seated controls and cabs.

Class 5 forklifts are similar to class 4 forklifts. Like class 4 forklifts, class 5 forklifts feature internal combustion engines, seated controls, and cabs. Unlike class 4 forklifts, they (usually) also feature pneumatic tires and counterbalancing.

Class 6 forklifts are tractors that feature either internal combustion engines or electric engines.

Class 7 forklifts include those forklifts that can work in rough terrains (rough terrain forklifts), like construction areas.

Equipment Components

Forklift trucks generally feature wheels, a fork or lift platform, a lift mechanism, operator controls, and an engine.

Wheels of a forklift truck can be fitted with outriggers for stabilization. They vary from solid rubber to pneumatic.

Forks or platforms are the space on which operators carry and transport material loads. They can be adjusted to different widths depending on their use. Most pallets have a standard size to accommodate the forks of a lift.

Lift mechanisms, which are literal fork lifts, designed for forklifts are usually powered with hydraulic hoses.

Controls may be next to a driver’s seat, or they may be in an area designed for the operator to stand and control the unit. Either way, controls allow the operator to raise and lower the load once it has been moved to the desired space. Also, the driver is always behind the forks so they can visualize the pallet they are lifting.

Forklift engines are either an internal combustion engine (gas powered) or an electric motor.

To increase maneuverability, many forklifts have tilting or rotating frames and wheels.

Forklifts are also loaded with safety features and attachments designed to protect drivers and the people around them. These features include sirens, horns, flashing lights, headlights, signal lights, a seat belt, and guard rails.

How to Safely Use Forklifts

While forklifts are excellent tools, put in the wrong hands, they can quickly become dangerous. That’s why you need to school both yourself and your workers on forklift safety.

1. Before turning on the forklift, you need to inspect it for damage and wear. Look at the important vehicle parts, like the tires and connectors, hoses, and other hydraulic tubing. Next, make sure that it has adequate fluid.

2. Once you’ve made sure that all of that is okay, you can board the forklift truck. Do so by taking a hold of the designated handlebars, and then pull or slide yourself in. Don’t jump in, as you could have an accident.

3. Now you can turn on the engine. You can’t operate it yet, though. Before moving the forklift, check to make sure all of your controls work. This includes your headlights, alarm systems, warning lights, and levers.

4. Next, look around you. Make sure your mirrors are properly positioned, and make sure no one and no large materials are in your blind spot. Alert any workers in the area that you plan to operate the forklift and wait until you know the area is clear.

5. Using a spotter, color coded paths, or physical barriers, ease your forklift into drive. Always drive slowly, and take turns carefully, especially when handling loads.

We also suggest you take the additional safety recommendations.

• Never turn with a raised fork or platform.

• Never operate your forklift outside the designated area.

• Do not turn on an incline.

• Never stop the forklift suddenly, but rather use gradual braking techniques.

• Look behind you before reversing.

• Never try handling a material load heavier than the max lift capacity of your forklift.

• Always keep loads aligned in the center of the fork/dispersed evenly.

• When handling loads, be aware of the ceiling height when raising loads.

For the best and most comprehensive safety recommendations, consult OSHA.

Things to Consider

To find a forklift that best fits your needs, you need to partner with a reliable forklift manufacturing company. If you are on a strict budget, consider seeking out a company that sells used forklifts. Trustworthy companies refurbish the forklifts and make sure that they are up to code and in near-new working condition. Even if you are not on the strictest budget, used forklifts can still be a great option.

To help you on your way, we have put together a list of some of the forklift suppliers we trust most. All of these suppliers offer high quality products and excellent customer service. These forklift truck sellers and manufacturers generally also offer forklift repair or maintenance service to help extend the lift’s lifespan. To decide which company is right for you, browse their company profiles, which you will find in the middle of this page. Pick out a few manufacturers you believe have the most potential for you, then reach out to representatives from each company to discuss your application. After speaking with them, compare and contrast each supplier’s forklift services, prices and products, and pick the company you want.

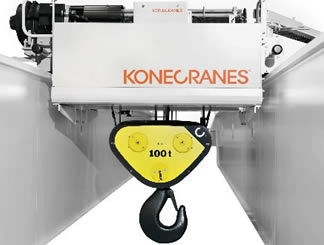

Cranes

Cranes Electric Hoists

Electric Hoists Forklifts

Forklifts Hydraulic Lifts

Hydraulic Lifts Rope

Rope Wire Rope

Wire Rope AGV

AGV Air Pollution Control

Air Pollution Control Assembly Machinery

Assembly Machinery Blowers

Blowers Conveyors

Conveyors Cranes

Cranes Deburring Machinery

Deburring Machinery Dust Collectors

Dust Collectors Heaters

Heaters Hose Reels

Hose Reels Lubricators

Lubricators Mezzanines

Mezzanines Modular Buildings

Modular Buildings Storage Racks

Storage Racks Ultrasonic Cleaners

Ultrasonic Cleaners Work Benches

Work Benches