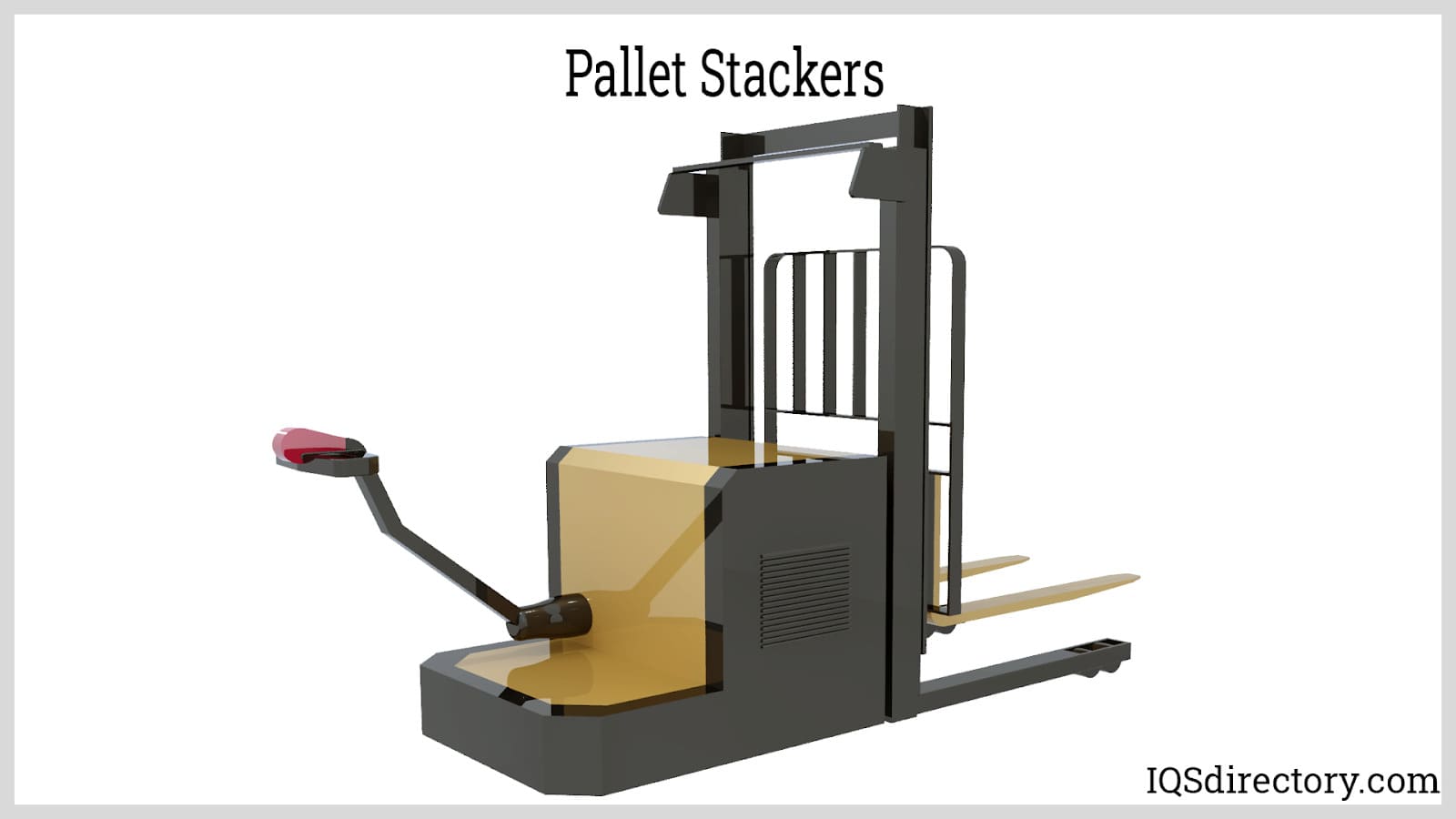

Typically, pallet stackers feature two power-operated prongs (forks). These forks may be raised or lowered for loading and unloading by sliding underneath the pallet and lifting it. The forks on pallet stackers slide underneath the pallet to raise it, and powered models feature an engine that houses any electrical or gas-powered equipment needed to operate the machine. Read More…

MHS Lift offers material handling equipment solutions, offering lift trucks, aerial equipment, personal carriers, floor cleaning equipment, parts, and integrated solutions. With a commitment to quality and customer satisfaction, MHS Lift delivers reliable, efficient, and innovative equipment designed to enhance productivity and safety in various industrial and commercial applications. MHS Lift...

Our goal at Crown Equipment Corporation is to provide you with the very best forklift trucks. These items are extremely reliable and can handle the toughest loads. We are eager to work with your business. We offer competitive pricing for premium quality forklifts.

Our solutions are guaranteed to help you save in operation costs. Our systems can easily be integrated with your facility and we strive to match your exact needs. Our engineers manufacture very powerful narrow aisle forklifts. It is our hope to create a long lasting business relationship with you. We engineer and fabricate a wide selection of heavy duty forklift trucks which are available new,...

There are a number of innovations emerging in the lift truck industry and we are a front runner of these newer technologies. The operations and advantages of our forklifts are unsurpassed. You can visit our website to receive full readouts regarding the attributes and capabilities of our lift trucks. We are happy to say that we are industry leaders for sales of quality lift trucks! Feel free to...

We have been providing material handling lifts and forklift truck equipment since 1984. Our forklifts and used forklift trucks range from 3,000 - 100,000 pounds. At Alta Lift Truck Services we are Michigan's premier choice with 8 locations, ISO 9001:2000 certified, and 24/7 service.

More Pallet Stackers Manufacturers

The pallet stackers may be divided into two groups: powered and manual. The most prevalent vehicles are counterbalanced forklifts, with prongs sticking out from the front and no foundation legs or outriggers supporting the cargo. These pallet stackers can raise the pallets relatively high off the ground and stack hefty pallets. These can often lift up to five tonnes. The load limit for the forklift's prongs is built-in and reduced with fork elevation and undercutting the load. Powered pallet stackers are less physically taxing on employees than manual pallet stackers since the prongs of the stacker are automatically lowered or raised.

Types of Pallet Stackers

- Manual Pallet Stackers: Pallet stackers operated manually are the most prevalent. These stackers use a hydraulic mechanism to move and raise pallets instead of an electrical control system.

- Semi-Electric Stackers: A semi-electric stacker is a different type of warehouse stacker. This kind combines manual and electric operations to create a hybrid. This device works well for stacking and moving pallets over short distances.

- Electric Pallet Stackers: An electric pallet stacker, usually a powered stacker, is the third and final form of a pallet stacker. Batteries and an electric motor are both used to power this model. Electric pallet stackers are the simplest to use since all their controls are electronic. The stacker moves swiftly and effectively across your warehouse thanks to its electric motor.

Construction of Pallet Stackers

- The maximum weight to be raised, the preferred fork width, and the lift height should all be noted in advance. The maximum number of pallets that may be stacked at once depends on the lift height.

- Both 4-wheel and 3-wheel configurations of counterbalance forklifts are available.

- Most pallet stackers are constructed from durable materials to resist breakdowns caused by frequent daily use and excessive weights.

- The pallet stacker's instability is a crucial feature. With each load movement, the pallet stacker must be viewed as a constantly shifting center of gravity unit.

- Warehouses and distribution facilities cannot function without pallet stackers. These devices must be built so that they can travel securely and effectively.

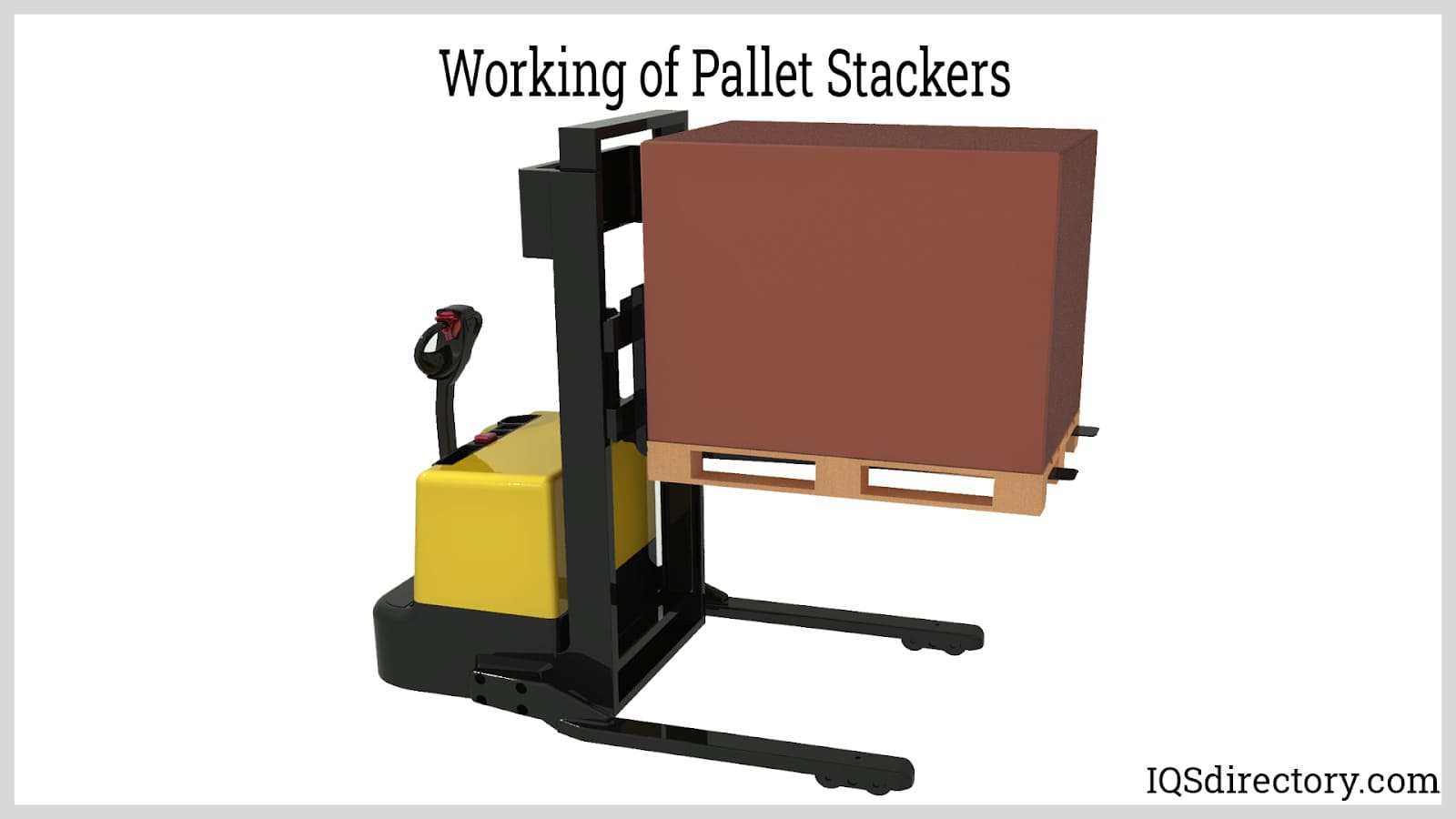

Working of Pallet Stackers

- Typically, levers, and machine handles are used to operate them.

- Most motorized forklifts include a steering wheel, making it possible to maneuver them virtually like a car.

- A control to raise and lower the forks is available, but the operator may tilt the mast to counteract a load's propensity to angle the blades downward which runs the danger of items falling off the forks.

- Additionally, tilt may offer a limited capacity for movement over uneven terrain.

- Hand-operated manual pallet stackers use hydraulics to make it easier to move oversized pallets.

- Typically, the jack is pushed or pulled into place to operate these pallet stackers.

- The stacker forks are typically raised by pressing a foot pedal and lowered by pulling a lever.

Benefits of Pallet Stackers

- Some pallet stackers may be equipped with an adjustable fork, allowing the fork to fit beneath pallets of various sizes or forms. This has the benefit of eliminating the requirement to buy several pallet stackers.

- Pallet stackers are easy to use and have a low entry barrier.

- Stackers are efficient and versatile since they are made to be quick and may be used in various professional contexts.

- Pallet stackers, which fall between a flapjack and a giant forklift, are one of the most affordable warehouse goods.

- Pallet trucks come in handy in warehouses when there isn't enough room for forklifts or other material-handling machinery.

- Stacker trucks are better suited for confined spaces than forklift trucks because of their increased maneuverability. They are perfect for carrying heavy items in cramped warehouses.

Applications of Pallet Stackers -

- Pallet stackers are frequently employed in facilities that handle mid-sized or high-volume commodities.

- Pallet stackers are incredibly helpful in warehouses that handle mid-sized or high-volume commodities. Thanks to its modest physical footprint, a stacker can easily and intuitively move into various configurations.

- They are accommodating for operations that call for more extended loading and maneuvering times with larger, heavier forklifts or manually operated non-motorized pallet carts.

- Pallet stackers are used in various sectors, such as manufacturing facilities, retail outlets, factory floors, and storage facilities.

Choosing the Right Pallet Stacker Supplier

To ensure you have the most beneficial outcome when purchasing a pallet stacker from a pallet stacker supplier, it is important to compare several companies using our directory of pallet stacker suppliers. Each pallet stacker supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or request a quote. Review each pallet stacker business website using our proprietary website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple pallet stacker companies with the same form.

Cranes

Cranes Electric Hoists

Electric Hoists Forklifts

Forklifts Hydraulic Lifts

Hydraulic Lifts Rope

Rope Wire Rope

Wire Rope AGV

AGV Air Pollution Control

Air Pollution Control Assembly Machinery

Assembly Machinery Blowers

Blowers Conveyors

Conveyors Cranes

Cranes Deburring Machinery

Deburring Machinery Dust Collectors

Dust Collectors Heaters

Heaters Hose Reels

Hose Reels Lubricators

Lubricators Mezzanines

Mezzanines Modular Buildings

Modular Buildings Storage Racks

Storage Racks Ultrasonic Cleaners

Ultrasonic Cleaners Work Benches

Work Benches