The forks are at a right angle to the truck’s body, and are therefore able to pick up loads to the side without turning. Read More…

MHS Lift offers material handling equipment solutions, offering lift trucks, aerial equipment, personal carriers, floor cleaning equipment, parts, and integrated solutions. With a commitment to quality and customer satisfaction, MHS Lift delivers reliable, efficient, and innovative equipment designed to enhance productivity and safety in various industrial and commercial applications. MHS Lift...

Our goal at Crown Equipment Corporation is to provide you with the very best forklift trucks. These items are extremely reliable and can handle the toughest loads. We are eager to work with your business. We offer competitive pricing for premium quality forklifts.

Our solutions are guaranteed to help you save in operation costs. Our systems can easily be integrated with your facility and we strive to match your exact needs. Our engineers manufacture very powerful narrow aisle forklifts. It is our hope to create a long lasting business relationship with you. We engineer and fabricate a wide selection of heavy duty forklift trucks which are available new,...

There are a number of innovations emerging in the lift truck industry and we are a front runner of these newer technologies. The operations and advantages of our forklifts are unsurpassed. You can visit our website to receive full readouts regarding the attributes and capabilities of our lift trucks. We are happy to say that we are industry leaders for sales of quality lift trucks! Feel free to...

We have been providing material handling lifts and forklift truck equipment since 1984. Our forklifts and used forklift trucks range from 3,000 - 100,000 pounds. At Alta Lift Truck Services we are Michigan's premier choice with 8 locations, ISO 9001:2000 certified, and 24/7 service.

More Narrow Aisle Forklift Manufacturers

Narrow aisle forklift trucks are commonly used in warehouse applications in constricted or constrained areas in which space conservation is an important factor. They are specifically designed to be used for offloading, material handling and storing within narrow aisles and as a result increase the amount of available storage within a space. Versatile models of narrow trucks are able to perform a variety of functions thus reducing the need for multiple forklift trucks and further saving costs.

Maneuverability, visibility and stability are all important considerations for choosing forklift trucks and will depend on the specifics of the application for which they are intended in terms of load size and weight and required motor power. Standard models of forklifts require approximately an 11 foot width to make turns, whereas narrow forklift trucks are able to complete turns in as little as 8 feet.

VNA forklifts, or very narrow aisle forklifts, are manufactured for spaces which are even smaller and these trucks have a potential turning circle of as little as 5 feet. More and more storage spaces such as manufacturing facilities, factories, storage warehouses and more are increasing space density by reducing aisle width, and forklift sizes follow accordingly.

Guidance systems in the form of laser measuring or computer technology assistance are often used to combat the mistakes made by narrow forklift drivers, or to effectively maneuver around the layout of the area. The reduction of working spaces makes industrial trucks more prone to collisions or errors. In order to avoid this, optical lines and wires can be used which run the length of the aisles and help keep the forklift on a consistent and straight path.

On many models of narrow truck, the forks are on the side of the truck's body, allowing the loads to be moved without the truck having to turn around in small spaces, therefore further reducing the possibility of collision. Employee safety is imperative and therefore forklift truck operators should be well trained in the operation and maneuvering of the vehicles. Further safety precautions may include an overhead guard, good seating and bumper pads on the truck itself.

Tire choice also plays a role in the comfort of the operator and affects whether or not a forklift truck may be used both indoors and outdoors. Traditionally, engine-operated forklift trucks were most common, but today, electric forklift trucks are becoming more popular, especially in accordance with new emission standards.

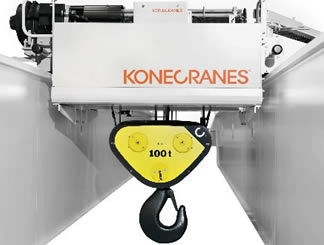

Cranes

Cranes Electric Hoists

Electric Hoists Forklifts

Forklifts Hydraulic Lifts

Hydraulic Lifts Rope

Rope Wire Rope

Wire Rope AGV

AGV Air Pollution Control

Air Pollution Control Assembly Machinery

Assembly Machinery Blowers

Blowers Conveyors

Conveyors Cranes

Cranes Deburring Machinery

Deburring Machinery Dust Collectors

Dust Collectors Heaters

Heaters Hose Reels

Hose Reels Lubricators

Lubricators Mezzanines

Mezzanines Modular Buildings

Modular Buildings Storage Racks

Storage Racks Ultrasonic Cleaners

Ultrasonic Cleaners Work Benches

Work Benches