Walkies are typically customized for specific heights or operations and can carry a load capacity up to 3,500 pounds. The proportional ergonomics and hydraulics of walkie forklifts allow for more sensitive lifting and lowering, as well as increased operator comfort which is an important element of industrial activity. Read More…

As a 30-year-old material handling distributor of fork lift trucks, used lift truck equipment, narrow aisle trucks and more, AJ Jersey® has material handling solutions. We offer electric lift trucks, walkie pallet jacks, rider pallet trucks, deep reach trucks, stock pickers and rental trucks.

Materials handling is more than just handling materials. And no one knows that better than Andersen & Associates, with over 50 years' expertise developing and deploying custom material handling solutions for the world's most trusted companies. No matter what industry you're in, we can provide you with lift trucks, fleet management, integrated systems and storage solutions that will satisfy.

Since 1978, Forklift Systems has grown from only 3 employees in a 4,500 sq. ft. building to a leader in sales, parts, service and rental of forklift trucks and other industrial equipment. We represent more than 12 major brands, including Nissan. New and used forklifts, forklift attachments and more.

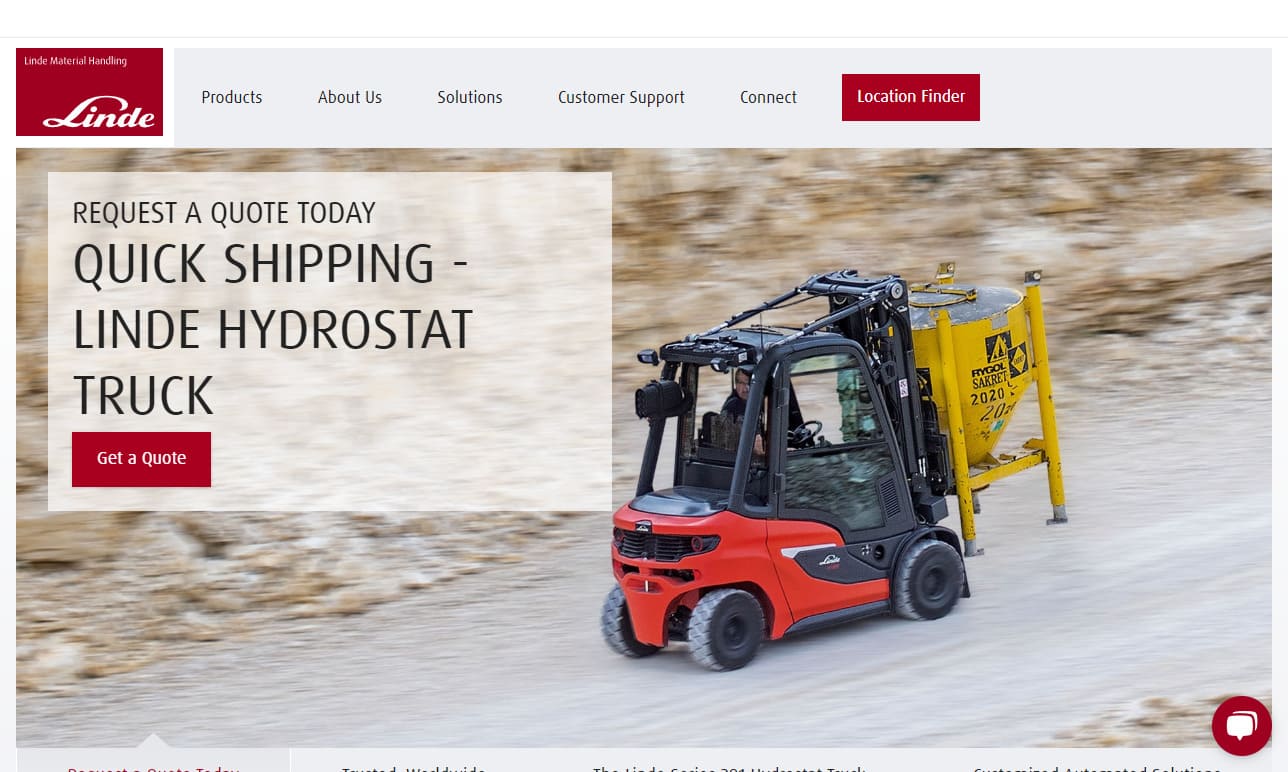

Our global network lets our product reach customers in a short time and our sales people are specialists in industrial trucks. Choose from turret truck models for high lift narrow aisles, electric-powered pallet trucks, center-ride pallet trucks, diesel and electric counterbalanced forklifts.

Reno Forklift specializes in the distribution of industrial material handling equipment and systems. Products include pallet racks, shelving, conveyor systems, dock equipment, workstations, work benches, scales, balers & compactors, wrapping equipment, strapping equipment, in-plant offices, cabinets, forklifts, utility vehicles, pallet jacks, lifts, elevators, cranes and hoists.

More Walkie Forklift Manufacturers

As with all other types of forklifts, operators have to be competent and well trained before controlling the vehicle. Walkie forklifts operate by electric power and are typically controlled by an operator directing from behind. The motor powers the forklift in order to move the heavy load. These are ideal vehicles for stacking in narrow or congested areas and those which require minimal turning circles and superior maneuverability.

Safety concerns are important to take into consideration when using walkie forklifts. The motor which helps to move the vehicle improves speed and ease of operation and when it is not engaged, the electric forklift will be stationary. The higher the voltage of the battery supply, the greater the power and lifting capacity a forklift will have.

Walkies are most commonly counterbalanced in order to prevent the vehicle from tipping over due to the combination of load weight and motion, especially when moving on a grade or around a turn. It is important to never move the forklift vehicle with a raised load as this offsets the balance of the machine. Other types of industrial trucks will use stabilizing legs and heavy duty masts which provide added structural strength to the procedure.

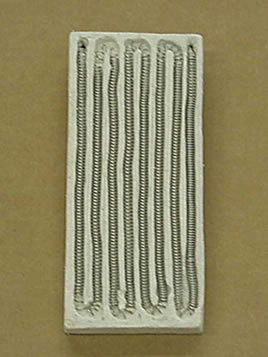

Walkie forklifts have optional foldable platforms, multiple lowering speeds and varying fork lengths and lift heights. The three main types of walkie forklift are forklift-fork-over, straddle leg and counterbalanced. Narrow aisle facilities use forkover trucks as they are the best designed for stacking in constricted spaces. Straddle leg trucks are designed with a stabilization leg allowing the forklifts to manage heavy loads and maximum heights.

Counterbalanced forklifts contain additional weights in the body of the truck that work against the weight of the load being handled. Counterbalanced forklifts are used instead of straddle-leg lifts when the stabilization leg prevents placing pallets close together. The extra weight prevents the forklift from toppling over when a load is raised or lowered by countering the applied tension of the load.

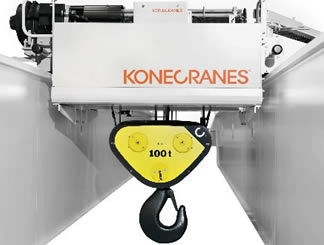

Cranes

Cranes Electric Hoists

Electric Hoists Forklifts

Forklifts Hydraulic Lifts

Hydraulic Lifts Rope

Rope Wire Rope

Wire Rope AGV

AGV Air Pollution Control

Air Pollution Control Assembly Machinery

Assembly Machinery Blowers

Blowers Conveyors

Conveyors Cranes

Cranes Deburring Machinery

Deburring Machinery Dust Collectors

Dust Collectors Heaters

Heaters Hose Reels

Hose Reels Lubricators

Lubricators Mezzanines

Mezzanines Modular Buildings

Modular Buildings Storage Racks

Storage Racks Ultrasonic Cleaners

Ultrasonic Cleaners Work Benches

Work Benches